NAVCO News

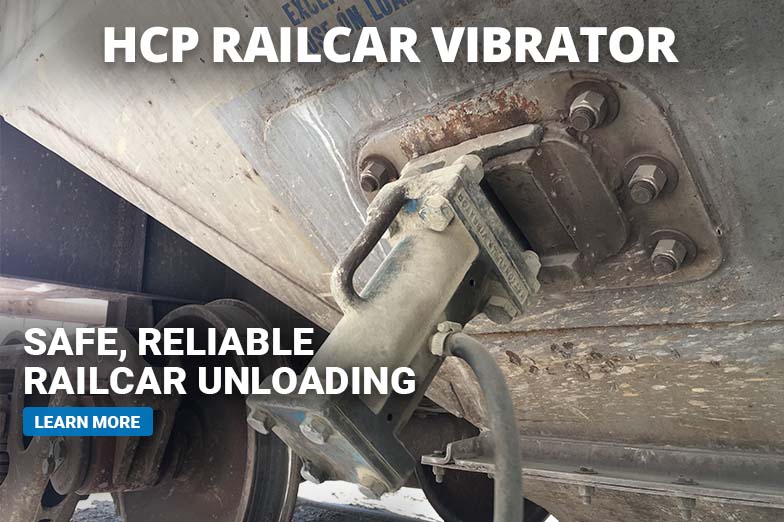

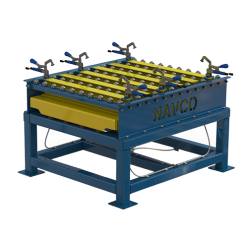

Railside Railcar Shaker Improves Unloading in Aggregate Yard

Unloading railcars at an aggregate yard is a crucial first step in the process for preparing material for loadout. How quickly and efficiently each railcar is unloaded has a significant impact on the productivity of the yard. When aggregates are brought in by rail, they often arrive in quantities of around 100 railcars at a […]Learn More