Products

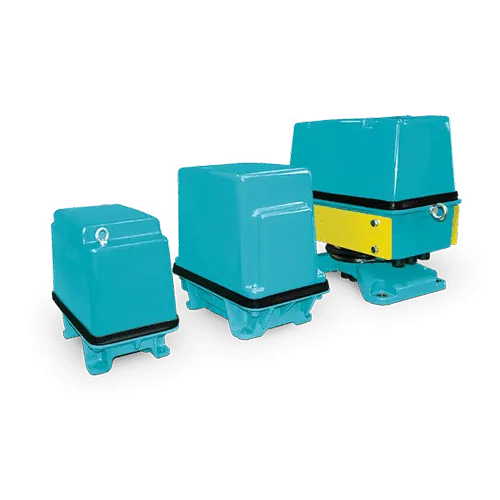

Pneumatic Vibrators

NAVCO® pneumatic vibrators promote material flow by eliminating the formation of bridges and rat holes in processing containers such as bins, hoppers, bunkers, silos, pipes, trucks, chutes, and other applications.

With over 15 pneumatic vibrator types available in multiple sizes, duty ratings, and mounting configurations, NAVCO can deliver a pneumatic vibrator to handle your application.

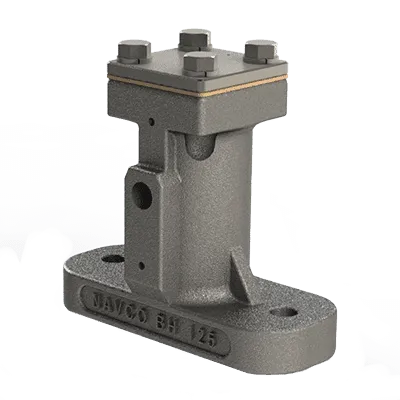

NAVCO® Bin Hopper Vibrators are pneumatic piston vibrators deployed across many industries to keep bulk material flowing in hoppers, silos, chutes, bins, totes, trucks, railcars, and more.

The NAVCO© Hopper Car Portable (HCP) Railcar Vibrator is a pneumatic piston vibrator that provides reliable and effective bulk material flow in difficult applications and harsh rail side environments.

Pipe and Chute Vibrators solve material flow problems in tight or closed spaces by reducing material strength and sliding friction. Available with pneumatic or electric drive options.

The NAVCO© BH Truck Vibrator aids in efficient unloading and loading of dry bulk material. These pneumatic piston vibrators increase material flow when unloading or increase load size when loading.

NAVCO® Match Plate Vibrators are high-quality pneumatic piston vibrators designed to attach directly to the match plate during the foundry casting process to improve mold density.

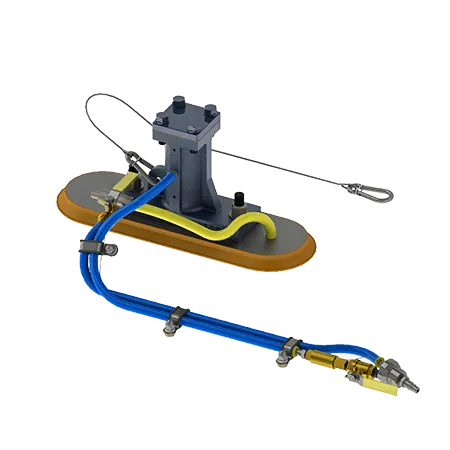

Engineered for bulk material applications with occasional material flow problems, the NAVCO® VacuVibe aids material flow in bins, hoppers, and containers where traditional mounting techniques are not an option.

Engineered for light-duty applications with occasional material flow problems, the NAVCO® MagneVibe attaches to the exterior of light-gauge walled bins through an incorporated magnet to aid material flow.

Largest in the BH Vibrator line, the NAVCO® Extreme Duty BH Vibrator is sized to eliminate material flow problems in large, heavy-walled chutes, bunkers, grizzlies, and other large storage vessels.

The NAVCO® Stainless Steel BH Vibrator provides material moving vibration for environments that require easy cleanability, ideally suited for light-duty bins and containers in the food, chemical, and pharmaceutical industries.

NAVCO® Molding Core Vibrators are high-frequency, heavy-duty pneumatic piston vibrators that ensure rapid, efficient core drawing and smooth surface finish for castings in foundry roll over molding machines.

NAVCO® Pneumatic Rappers remove dust from collecting plates, discharge electrodes, gas distribution systems, and collection hoppers in electrostatic precipitators (ESP). They are durable across a wide range of climate conditions.

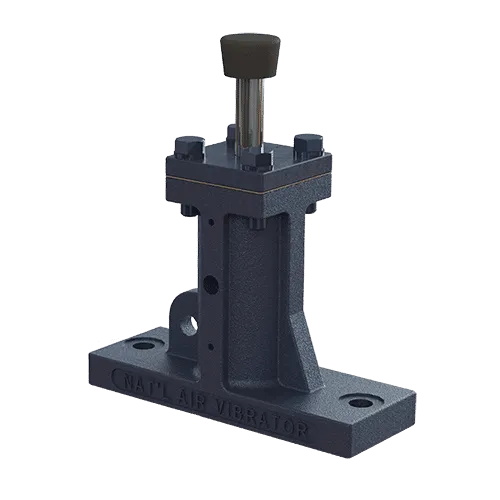

The NAVCO® FV Vice Mount Vibrator is a portable vibrator that aids settling in forms, uniquely designed to eliminate the need for special mounting brackets required in other models.

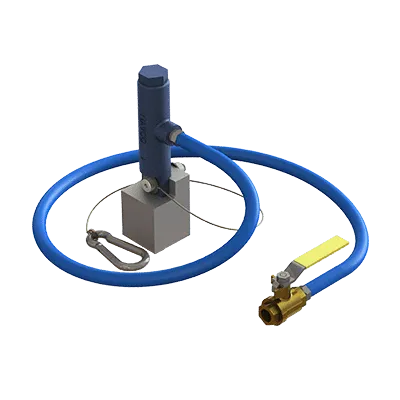

The NAVCO© ExtendoVibe is a vibratory solution where other vibrators are not feasible due to process limitations, including portable container stations, bulk bags, plastic hoppers, and intermediate bulk containers.

NAVCO® Form Vibrators are pneumatically driven rotary vibrators that promote faster consolidation, and superior surface finishes on battery molds, compaction tables, forms, and molds for concrete shapes.

NAVCO® Ball Vibrators are rotary vibrators that keep material flowing wherever it’s housed. Compressed air creates a non-impacting high frequency, low amplitude vibration for densification and material flow.

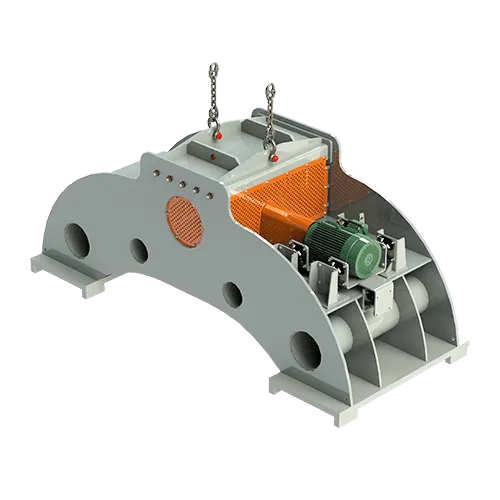

Electric Vibrator

NAVCO® electric vibrators are used to drive vibratory equipment and also have applications in facilitating material flow out of storage containers.

NAVCO offers two configurations: rotary electric and electromagnetic with light-duty to heavy-duty applications in extreme environments and temperature ranges. With hundreds of variations, there is an electric vibrator to meet the specific needs of your application.

Rotary Electric Vibrators feature sturdy electromechanical motors to handle a wide range of applications, from light-duty material flow solutions to powering heavy-duty vibratory equipment.

Electromagnetic Vibrators feature adjustable frequency, which allows the drives to provide the precise vibration required to ensure superior product quality and promote long operational life.

Vibratory Equipment

NAVCO® vibratory equipment are engineered vibratory solutions for bulk material processing. Our custom-designed equipment cover a wide range of applications for material compaction, de-nesting, loading, unloading, feeding, and more.

NAVCO equipment serves light-duty, heavy-duty, and extreme heavy-duty environments, including railcars, trucking, mining, and foundry, as well as pharmaceuticals and food processing.

NAVCO® Vibrating Tables apply vibration to automate labor intensive processes across many industries and enable you to increase productivity and enhance the quality of your products.

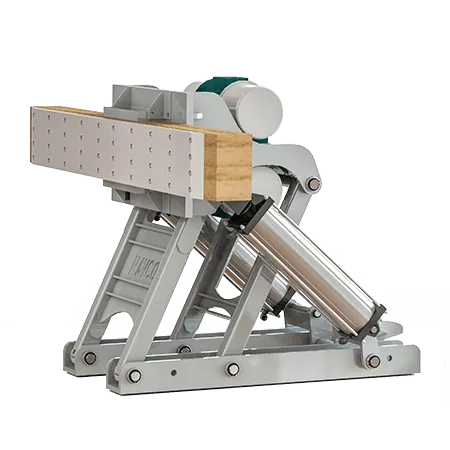

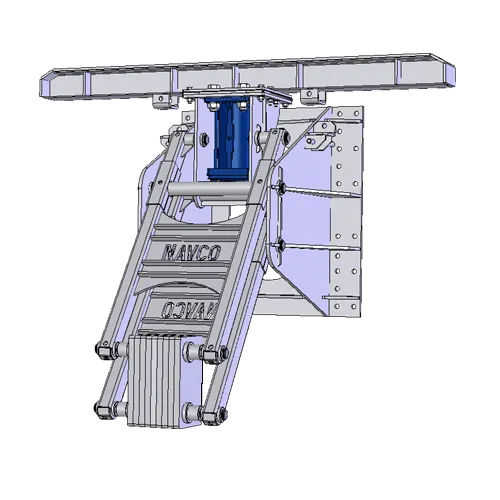

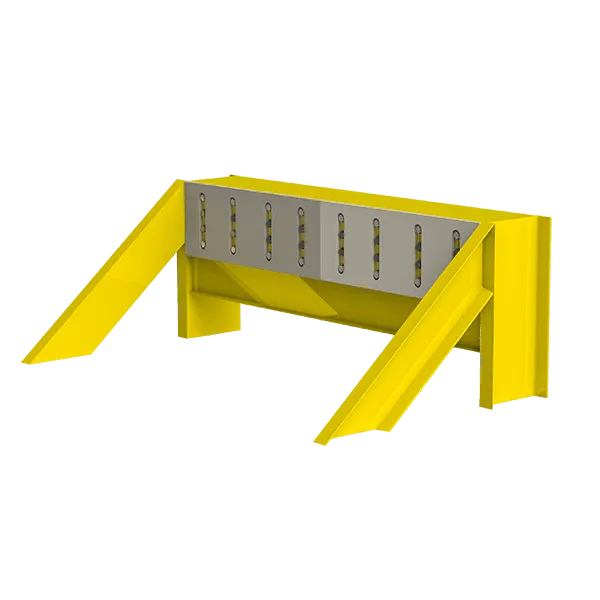

Designed for unloading from hopper railcars in heavy-duty applications and harsh environments, the NAVCO® Railside Railcar Shaker is sized to handle difficult to move bulk materials.

Designed for unloading open-top hopper railcars in heavy-duty applications and harsh environments, the NAVCO® Overhead Railcar Shaker works where other railcar vibrators fall short.

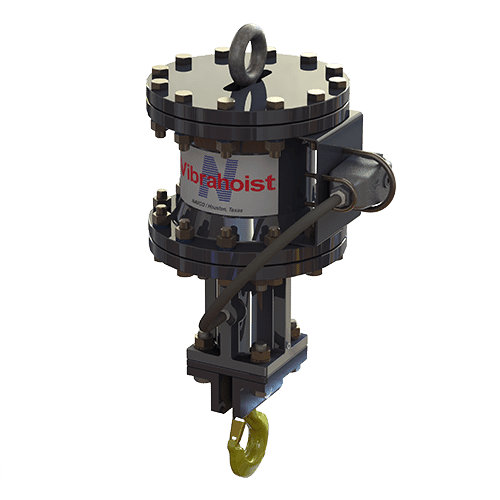

The NAVCO® VibraHoist System applies vibration to a suspended load, used most often in the galvanizing industry to remove excess zinc from recently treated large and heavy parts.

NAVCO® Pneumatic Vibratory Feeders are versatile, time tested performers where bulk material feeding and conveying are required in hazardous locations. Available in a variety of sizes and options.

Designed for unloading bulk material from hopper railcars in heavy-duty applications and harsh environments, this NAVCO® vibration system is sized to handle difficult to move bulk materials.

The Truck Dumper Shaker from NAVCO® applies vibration to loosen packed material for continuous flow of bulk material from trucks and trailers, where unloading is done with truck dumpers.