Vibration for dump truck and trailer unloading eliminates use of sledge hammers

Dump truck and trailer unloading can go from an easy job to a time consuming one, depending on the material the truck is hauling and the weather conditions. In the past, truck drivers have come up with ways to deal with sticking material by swinging sledge hammers and “bouncing” the truck in an effort to get the material to flow. Although these methods of encouraging material to flow sometimes do end up working, they come with safety concerns for both people and equipment. Because of this, many companies have implemented restrictions on the use of sledge hammers and jolting as a means of getting material to flow.

A trucking company reached out to NAVCO after a customer of theirs implemented new safety measures that restricted these techniques. The trucking company was hauling fly ash, which is typically mixed with water prior to transportation to limit dusting. Mixing the fly ash with water causes the material to become sticky, and creates difficulties in unloading due to the wetted material’s low flowability. The trucking company needed a solution to reliably and safely unload the stubborn material in order to continue to keep their customer supplied with product.

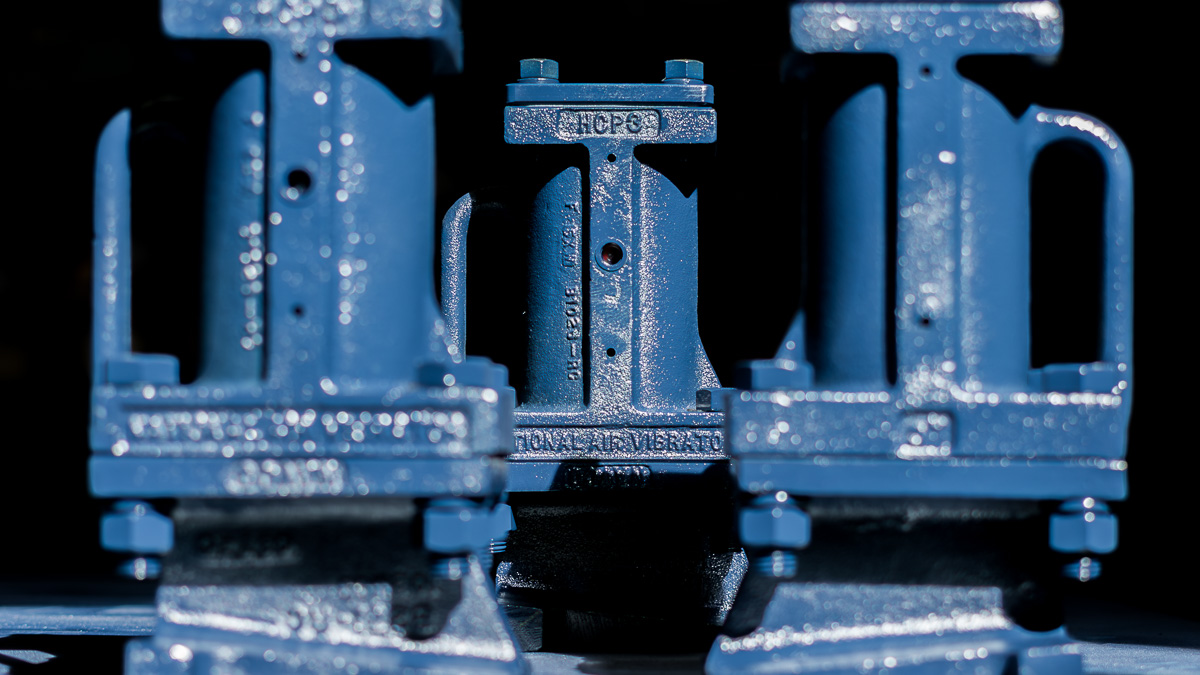

The trucking company contacted NAVCO seeking help formulating a solution for their material flow problem. The company used two aluminum 40 ft. end dump trailers for transporting the fly ash. After discussing the details of the trailer construction and material properties, NAVCO selected our BH Truck Vibrators to deliver the best vibration for dump truck and trailer unloading. These repetitive impacting pneumatic piston vibrators deliver a high energy impulse, which excels at encouraging flow of sticky materials. The two BH units were spaced along the trailer, to ensure influence of material over the entire length.

The customer was in immediate need of the vibrators to get their dump trailers back on the road and delivering material. Our local representative in the area made contact with the customer and confirmed that the units were in stock and ready for pick up. When the customer arrived to collect the equipment, the local representative was able to examine the trucks and provide guidance on the exact placement of the BH Truck Vibrators to optimize results in the given work envelope.

The dump truck and trailer unloading vibrators were installed that afternoon and the trucking company began hauling fly ash to their customer’s site with the newly outfitted trailers the next day. With the aid of the vibrators, the material was quickly and completely dumped from the trailers, while maintaining compliance with the site’s new safety requirements. The NAVCO BH Truck Vibrators greatly improved unloading efficiency of the difficult fly ash and the trucking company has begun the process of outfitting their fleet of dump trailers with identical vibrator systems.

NAVCO is the leading manufacturer of industrial vibrators and vibratory equipment and have been solving bulk material flow problems for over 60 years. By incorporating the most advanced manufacturing techniques, quality control, and bulk solids flow technology, NAVCO provides effective solutions for unloading bulk materials from dump trucks. Contact NAVCO today for help improving your dump truck unloading processes.