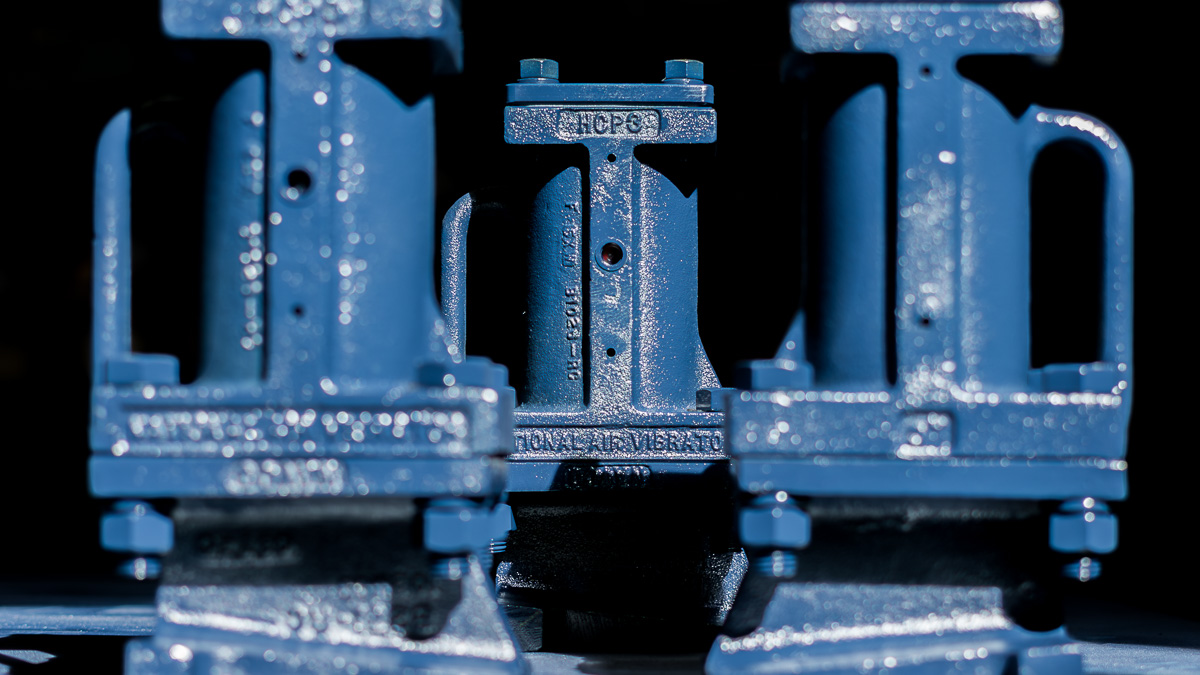

Pneumatic Air Piston Vibrator Solutions

For more than 65 years, NAVCO has provided North American industry with piston vibrators that keep bulk materials flowing. Utilized across a wide range of industries these vibrators have kept sand, minerals, metals, plastics, chemicals, pharmaceuticals, grains, food, and more moving along the production line. By stopping these materials from clogging up silos, railcars, bins, hoppers, and vessels piston vibrators have become an integral part of many manufacturing applications.

Inconsistent Bulk Material Flow Kills Process Efficiency. NAVCO engineers have tested and improved the application of industrial vibrators for over 65 years, refining the design to target the different ways material flow problems can present themselves. This includes incorporating the ability to customize the vibrator, providing solutions for a diverse range of industries and applications.

What is a Pneumatic Air Piston Vibrator and How Does it Work?

This equipment utilizes compressed air to power the back and forth motion of the piston within the vibrator. That motion creates vibration necessary to dislodge clogged bulk material. The vibration is transferred from the vibrator to the bulk material container creating a bin response that will break up the stuck material. The challenge is to create a bin response so that the material “bridges” and “rat holes” that form in the container are eliminated and the material can keep flowing freely.

65 years of testing and improvement means NAVCO can deliver the right product for the right job in each situation. Made in the USA, NAVCO provides pneumatic piston vibrators in more than 10 sizes that generate vibration three different ways:

Repetitive Impact

Impacting units deliver a high-energy impulse with each stroke of the piston. The impacting model is the most effective of the three in eliminating difficult flow problems.

Single Impact

Where one high energy impulse is necessary to restore material flow, a single impact model can be triggered by a timer or other controlling device.

Silent

Silent models trap air at the base of the piston, eliminating the high energy impulse and reducing noise levels. The resulting gentle vibration helps maintain movement of flowable materials.

But Will It Work in My Factory?

NAVCO engineers work with you to customize BH vibrators for a wide range of specific manufacturing applications. These customizations provide solutions for applications including:

Corrosive / Washdown

Food Grade / Sanitary

High Temperature

No Weld Environments

Unique Work Envelopes

Process Integration

Local representatives are available for onsite consultation to facilitate seamless integration into your current application or process.

NAVCO has been solving bulk material flow problems using pneumatic piston vibrators for over 65 years. Incorporating the most advanced manufacturing techniques, quality control, and bulk solids flow technology, NAVCO provides effective solutions utilizing reliable, field-proven equipment. Contact NAVCO or speak with a knowledgeable representative in your area.