Bulk material densification increased bin fill weight by average 10%

Many industries struggle to meet their target weight/ fill levels in bulk material containers. Material not densifying enough within its container during the loading process can create costly delays, reduced margins, higher shipping costs, and constrain plant capacity. To combat these costly inefficiencies many operators resort to unsafe and destructive practices, such as hammering or manually shaking containers to densify the material and improve their container loading.

NAVCO was approached by a carbide processing facility who was missing their desired bin fill weight of 5,000 pounds by an average 10% per bin. The facility is filling hundreds of bins per week with carbide. By increasing each bins fill weight by ten percent would help improve the facilities productivity by an average of 20 additional bins in weight over a seven-day period.

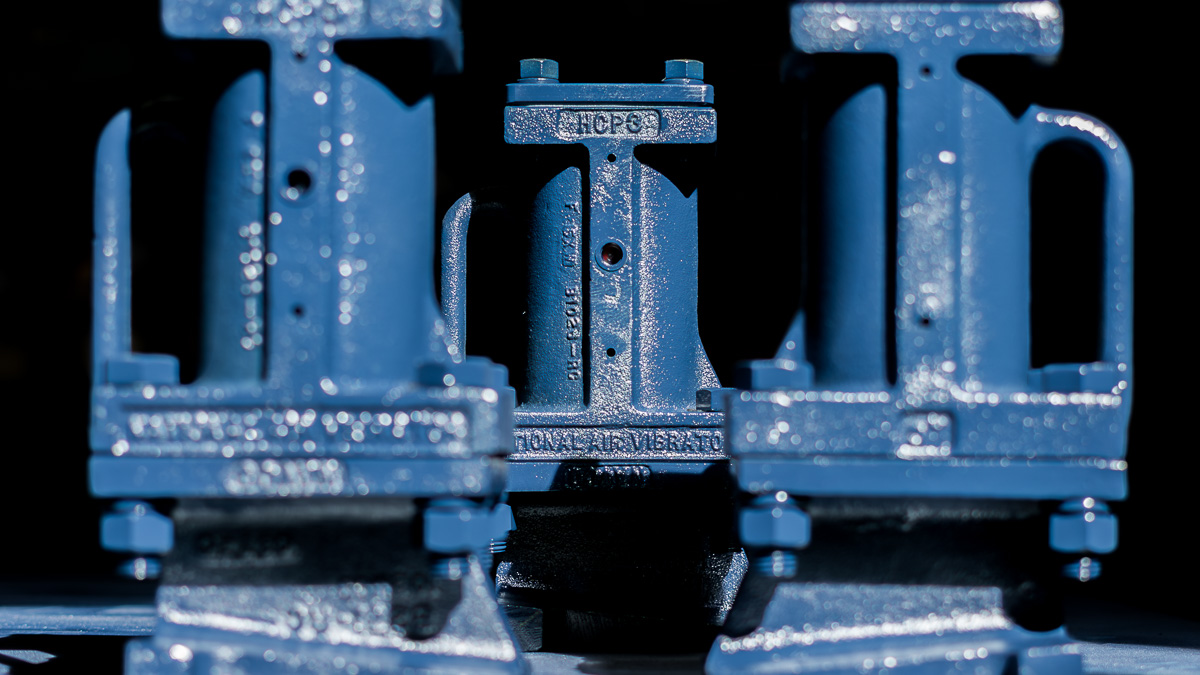

After speaking with the customer about their process, NAVCO engineers suggested an efficient and effective solution for this application, the VacuVibe 2.00. The VacuVibe combines the rugged, powerful performance of the NAVCO BH 2.00 vibrator with the portability of a pneumatically driven vacuum mounting pad. This solution offers powerful vibration and increased utility, while also representing a significant cost-effective solution over other options.

NAVCO VacuVibe 2.00 bulk material densification:

- 2” nominal diameter piston vibrator.

- 14’’ of air hose.

- Manual valves for vibrator and vacuum mount control.

- Pressure regulator for vibrator operating pressure.

- 3/8” NPT male quick connect fitting.

- Safety cable and latch.

NAVCO engineers proposed the use of the VacuVibe because of its two key features powerful vibration and portability:

Powerful Vibration

The BH 2.00 vibrator utilized on the VacuVibe is able to provide targeted high amplitude, low frequency vibrational force into the bin. The vibration relieves trapped air and encourages geometric alignment of the particles helping the material obtain optimum bulk density. The need to stop the process, hammer on bins, or manually shake the containers is eliminated.

Portability

The vacuum mount enables the vibrator to be moved easily from bin to bin, eliminating the need for multiple pieces of equipment. The portability also allows the operator to target problem areas directly with the vibrator ensuring the carbide densifies enough to meet the target weight per bin.

The customer agreed with NAVCO’s solution and have incorporated the VacuVibe into their process. They are currently running two VacuVibes in their facility have consistently been meeting their target fill weights. This has increased their productivity allowing them to process around 20 more bins per week. If you are in need of a portable solution for your bulk material flow problems, contact NAVCO today! With over 65 years of experience, NAVCO has the knowledge and equipment to maximize your bulk material handling processes.