Railcar Unloading Vibrator promotes material flow, protects workers and equipment, and ensures timely unloading

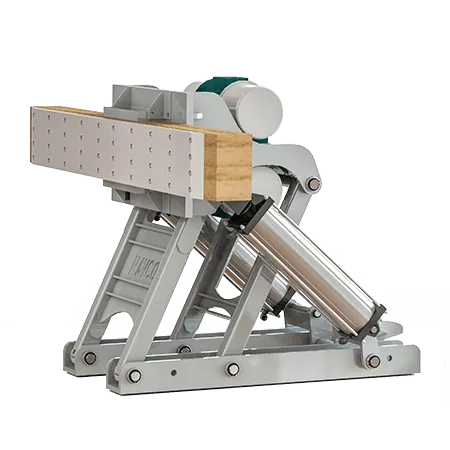

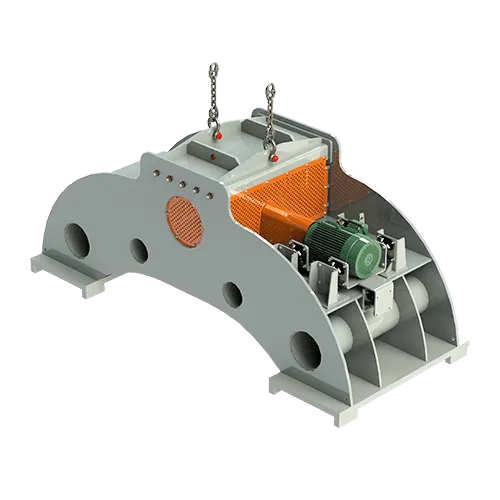

The NAVCO Hopper Car Portable (HCP) Railcar Vibrator is the original member of the NAVCO family of railcar unloading vibrators and shakers which includes the Railside Car Shaker and the Overhead Railcar Shaker.

Primarily used for unloading covered hopper railcars, the HCP Railcar Vibrator promotes material flow, protects workers and equipment, and ensures timely unloading.

When unloading railcars, operators can encounter stuck material that hinders, and even stops, material from flowing. This stuck material manifests itself in three common ways:

Compaction (No Initial Flow)

While in transport, material can compact at the hopper discharge at the bottom of the railcar. This compacted material at the discharge blocks any material from exiting when the discharge is opened.

Bridging (Arching)

This occurs when some materials have sufficient strength to bridge during the unloading process. This allows material sitting under the bridge to exit the hopper, but stops any material above the bridge from exiting.

Rat Holing

Similar to bridging, some materials have sufficient strength and sliding friction factors that resist flow, especially along the railcar walls.

Without the help of an HCP Railcar Vibrator, these issues require railcar operators to do anything they can to get the material unstuck and moving out of the hopper railcars, even slamming the hopper car with sledge hammers or climbing inside the cars to scrape and break up sticking material. These labor and time-intensive solutions slow down the unloading process, can damage railcar equipment, and are hazardous to operators.

HCP Railcar Vibrator Solves Material

Compaction, Bridging, and Rat Holing

NAVCO HCP Railcar Vibrator provides reliable and effective vibration that solves these three common stuck material issues and allows hopper railcars to be unloaded quickly and efficiently. The HCP Railcar Vibrator connects to hopper railcars by sliding into the universal mounting bracket, a standard fixture on many hopper cars. When activated, the vibrator runs within the universal mounting bracket, causing a continuous vibration response by the hopper wall. This response reduces the material’s cohesion and sliding friction, which restores flow to the compacted, bridged, and/or rat holed material. By utilizing HCP Railcar Vibrators, railcar operators can restore flow in stuck materials and unload their hopper railcars quickly and efficiently.

NAVCO has over 65 years of experience providing applied vibration solutions to the challenges of unloading covered hopper cars. The NAVCO HCP Railcar Vibrator enables quick and easy unloading of bulk materials from hopper railcars. If you are dealing with sticking material when unloading bulk materials from hopper cars, the NAVCO HCP Railcar Vibrator may be your solution. Contact Us Today to answer any questions about sticking material in your hopper railcar.