Duke Energy deploys power plant pipe vibration to improve material flow

Pipes and chutes are used in many industries to move material quickly and efficiently within the facility or plant. While these are often the best solution for moving material between areas of the process, they can be a primary source of material flow constraints, such as plugging. Conventional techniques to restore flow, like hitting the pipes and chutes with hammers, provide a temporary solution with a long-term cost. Hitting the equipment continually can cause dents that constrict the materials ability to flow.

Duke Energy Company had been dealing with this power plant pipe vibration issue in their coal chutes for some time. The material was plugging in the chutes above the pulverizers, which was leading to de-rating of the generator. In an attempt to solve this, they had tried using a portable vibrator that was strapped onto the pipe using worm gear pipe clamps. This solution resulted in poor vibration transfer to the material in the pipe and the operators had to continue using manual means to achieve coal flow in the chutes.

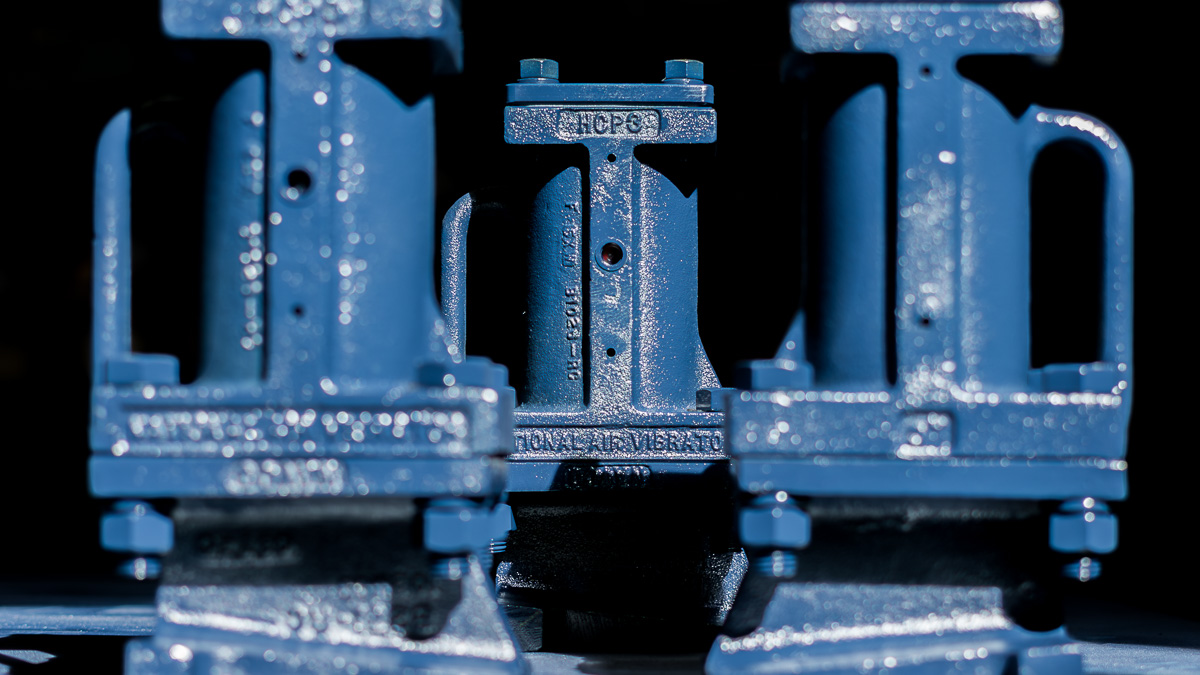

After discussing the issue with Duke personnel, NAVCO proposed utilizing a Pipe and Chute BH Vibrator on the chutes to solve the coal flow issue. The vibrator would utilize a custom mount designed specifically to the diameter and wall thickness of the pipes at the facility. The mount of the vibrator is engineered to reinforce the pipe it is installed on, and help maximize the transfer of vibrational energy through the wall and around the circumference of the pipe. The bolt on design of the mount also allows for easy installation without the need to pull hot work permits to complete installation of the vibrator.

Duke agreed and installed the recommended power plant pipe vibration solution on the coal chutes at the facility. After using the vibrators for a couple of weeks the facility reported back that they were a complete success. Lead Project Engineer, Chuck Yarbrough, said that the operators wish they had installed these units years ago.

Chuck said the NAVCO vibrators proved to be much more effective, while using less than half the air consumption than other solutions that were tried. Now when a clog is detected, an operator just has to initiate the vibrator for a few seconds, and flow is quickly restored.

“These vibrators corrected a problem we have struggled with for years.”

NAVCO Pipe and Chute BH Vibrators provide non-destructive, material flow restoring vibration to pipes and chutes.

Dealing with material flow issues in your pipes and chutes? Contact NAVCO Today, and get your material flowing.

Learn more about NAVCO Pipe and Chute BH Vibrators